Direct Metal Printing (DMP) gives you complete design freedom to manufacture stronger parts that are light, durable and perform better than other means.

Direct Metal Printing (DMP) gives you complete design freedom to manufacture stronger parts that are light, durable and perform better than other means.

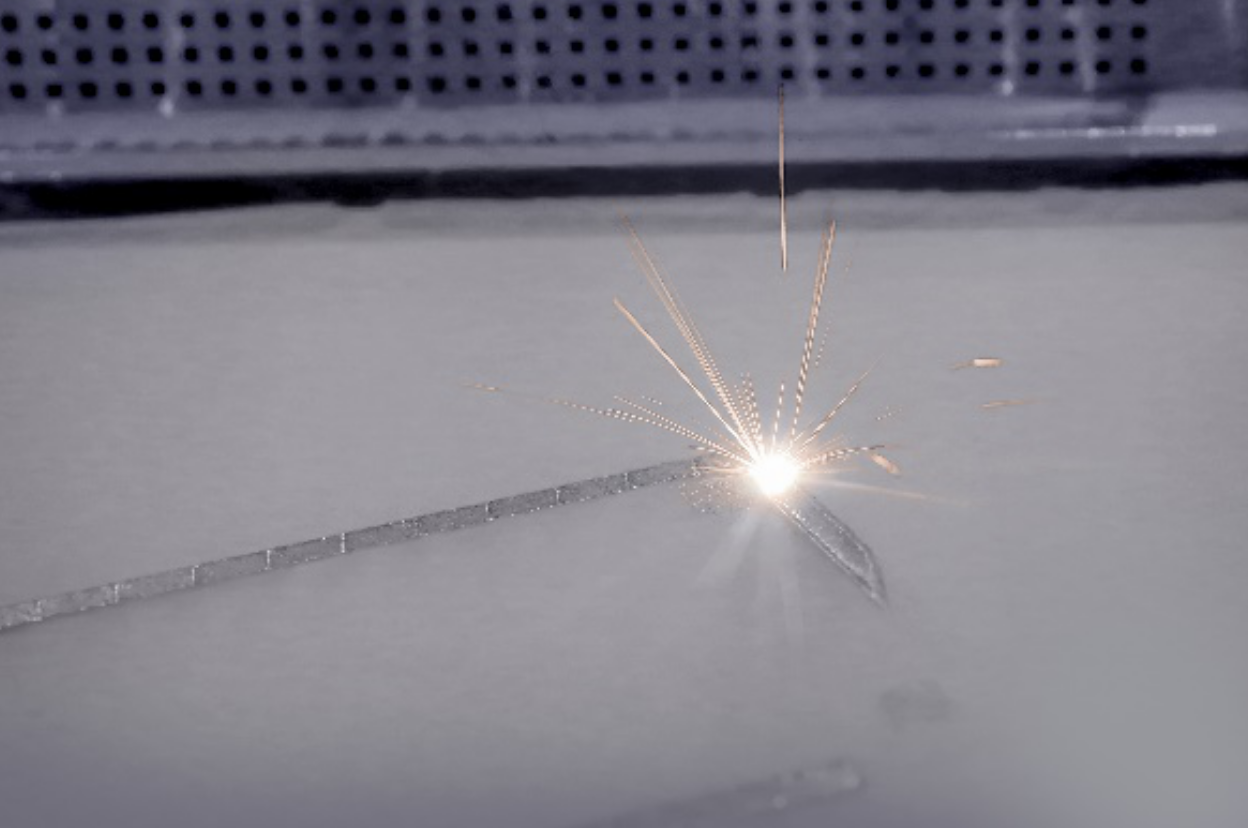

Direct metal laser sintering (DMLS) is an industrial metal 3D printing process that builds fully functional metal prototypes and production parts in 7 days or less. A range of metals produce final parts that can be used for end-use applications.

Aluminum are highly favored for their lightweight, high strength, and excellent corrosion resistance, making them particularly suitable for manufacturing high-performance components in aerospace and automotive sectors. Using metal 3D printing technology, we can precisely fabricate complex, lightweight structures that are challenging to achieve with traditional manufacturing methods. Additionally, the high thermal conductivity and recyclability of aluminum alloys also make them outstanding in terms of environmental protection and energy efficiency. Our processing technology ensures that every product fully utilizes the advantages of aluminum alloys to meet the industry's demand for innovation and sustainable development.

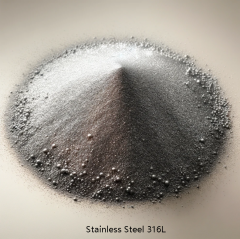

Stainless steel is highly prized for its excellent corrosion resistance, high strength, and superior heat resistance, making it ideal for manufacturing complex industrial components and durable consumer goods. With metal 3D printing, we can achieve highly customized designs, precisely construct every detail, while ensuring structural durability and longevity. This advanced manufacturing technology not only improves production efficiency but also optimizes material usage, making it the perfect choice for the aerospace, medical, and automotive industries.

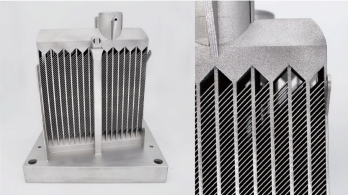

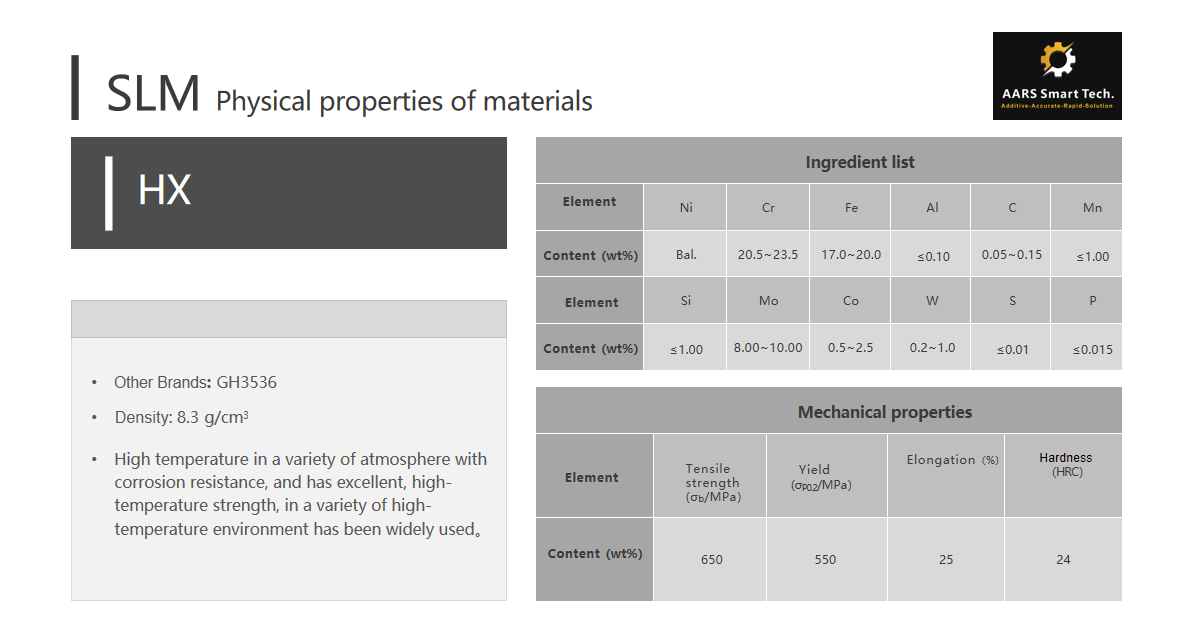

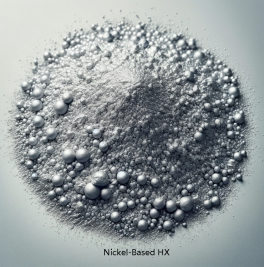

Nickel-based are highly esteemed for their exceptional stability under extreme high temperatures and strong corrosion resistance, making them the ideal choice for aerospace, energy, and high-temperature industrial applications. These alloys can withstand harsh environments and maintain structural integrity, making them suitable for manufacturing complex engineering components. Through precise metal 3D printing technology, we can create finely designed, high-standard nickel-based alloy parts that enhance product performance and extend lifespan. This innovative material solution provides robust support for industries facing extreme challenges.

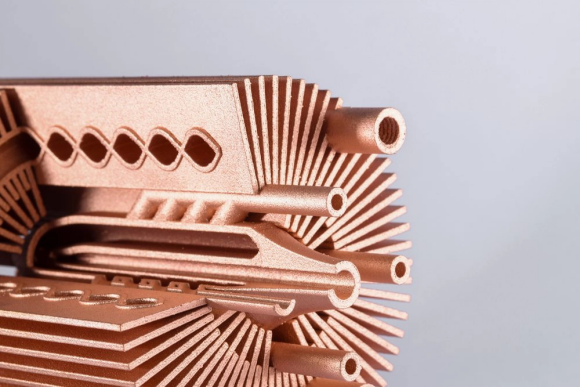

Copper materials used in metal 3D printing are highly valued for their excellent electrical and thermal conductivity, making them ideal for high-tech and industrial applications. Our processing factory utilizes advanced metal 3D printing technology to precisely manufacture copper parts, capable of creating complex structures with superior performance. This material also boasts good corrosion resistance, ensuring long-term stability. These unique properties of copper make it extensively applicable in electronics, aerospace, and automotive industries, offering designers greater innovation space and flexibility in applications.

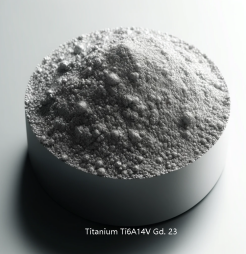

Titanium demonstrate unique advantages in metal 3D printing, with their high strength-to-weight ratio and excellent corrosion resistance making them ideal for aerospace, biomedical, and precision engineering applications. This material is not only lightweight but also highly durable, capable of withstanding extreme environmental challenges. Using Metal 3D printing technology, we can accurately create complex-shaped titanium alloy components that fully utilize their mechanical properties to meet the demands of high-performance applications. These characteristics of titanium alloys allow us to innovate in design and functionality across a broader range of industries.

Cobalt-based are favored for their exceptional wear resistance and high-temperature capabilities, making them especially suitable for use in harsh working environments. These materials are widely used in the aerospace, automotive, and medical device industries to manufacture complex and durable components. Our metal 3D printing technology enables the precise fabrication of cobalt-based alloy parts with superior mechanical properties, ensuring long-term stable performance. The high performance of cobalt-based alloys makes them an ideal choice for demanding applications, driving continuous technological advancement in the industry.

It is a thermoplastic polymer structural material with high strength, good toughness and easy processing. It is also a low-cost engineering plastic with good processing performance, strong mechanical properties, and a wide range of applications, making it an excellent choice for production parts.

Polycarbonate, referred to as PC engineering plastics, an amorphous thermoplastic resin with excellent comprehensive properties, an engineering plastic with excellent electrical insulation, ductility, dimensional stability and chemical resistance, high strength and weather resistance.

Nylon(PA). Also known as polyamide

It is the most important engineering plastic, covering almost every application field, widely used in chemical machinery, anti-corrosion equipment gear and parts blanks, transmission structural parts, household appliance parts, auto parts, etc.

PMMA:(polymethyl methacrylate)Also known as acrylic

It has the characteristics of good transparency, chemical stability and weather resistance, easy dyeing, easy processing, good plasticity and beautiful appearance. It is widely used in medical, industry, automobile and other fields. However, its thin-walled areas are fragile during machining, so it is not recommended for delicate or complex geometries.

POM (polyformaldehyde) is an engineering plastic with high hardness, high rigidity and high wear resistance. It has good surface hardness and compactness, and is suitable for gears, bearings, auto parts, machine tools, instrument internals and other products that play a skeleton role.

PEEK (poly-ether-ether-ketones) is a high-performance specialty engineering plastic that is an excellent lightweight alternative to most soft metals. It has excellent mechanical properties, good self-lubrication, chemical resistance, and good wear resistance. Commonly used in aerospace, automobile manufacturing, electrical and electronic, medical, and other fields.

It is one of the lightest varieties of all plastics at present; it has the characteristics of high heat resistance, good mechanical properties, environmental protection and non-toxicity. It is suitable for making general mechanical parts, corrosion-resistant parts and insulating parts.

Commonly known as "Plastic King", it has excellent properties such as high and low temperature resistance, chemical corrosion resistance, small friction coefficient, self-lubrication and non-stickiness. Widely used in aerospace, electronics, electrical, chemical, machinery and other industries.

Direct metal laser sintering (DMLS) is an industrial metal 3D printing process that builds fully functional metal prototypes and production parts in 7 days or less. A range of metals produce final parts that can be used for end-use applications.