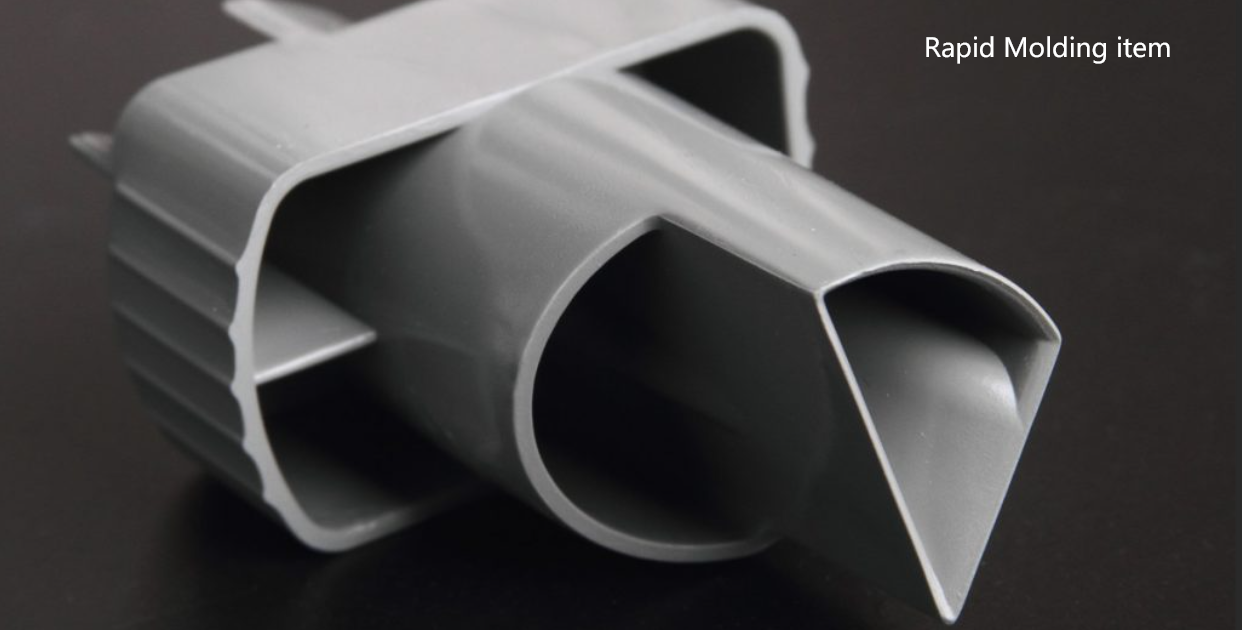

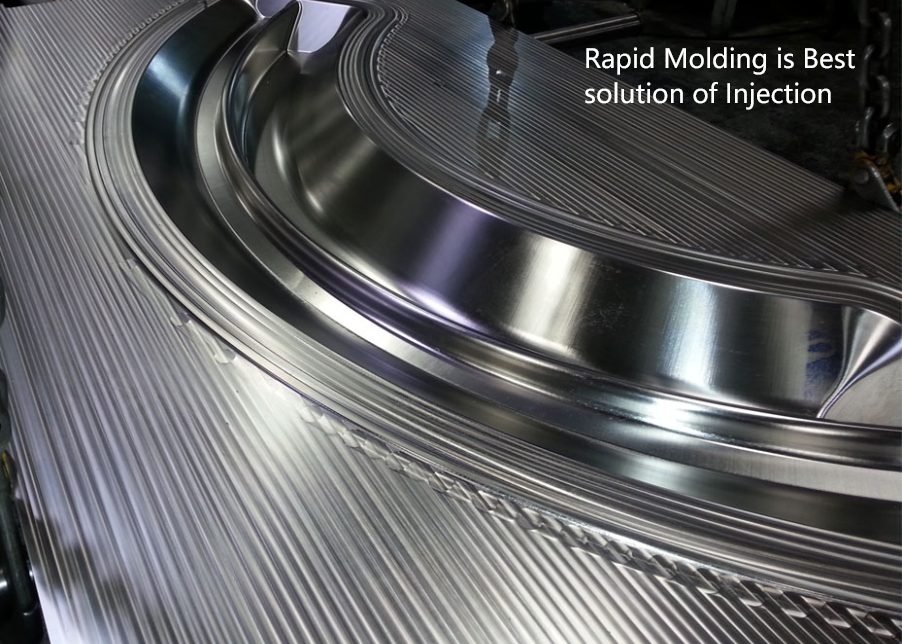

What is Rapid Molding? Rapid Molding is a specialty service for making certain kinds of plastic injection mold tools and finished parts in a fraction of the time it takes to make full-production volume tools. It relies on optimizing the design, fabrication, and materials to achieve maximum production efficiency and minimal downtime.