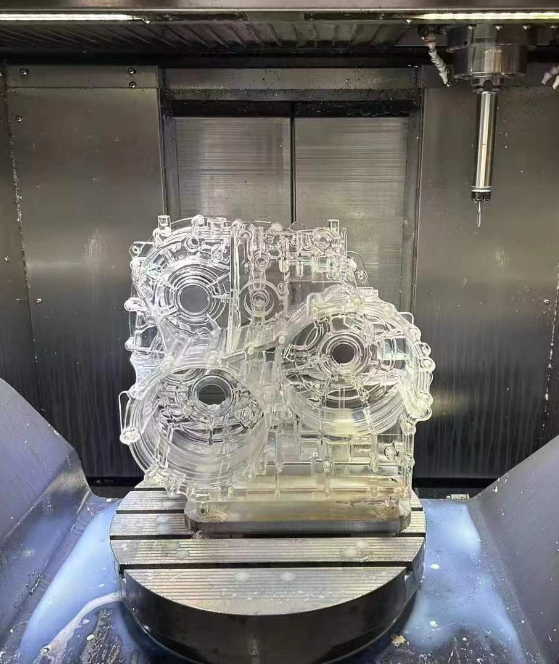

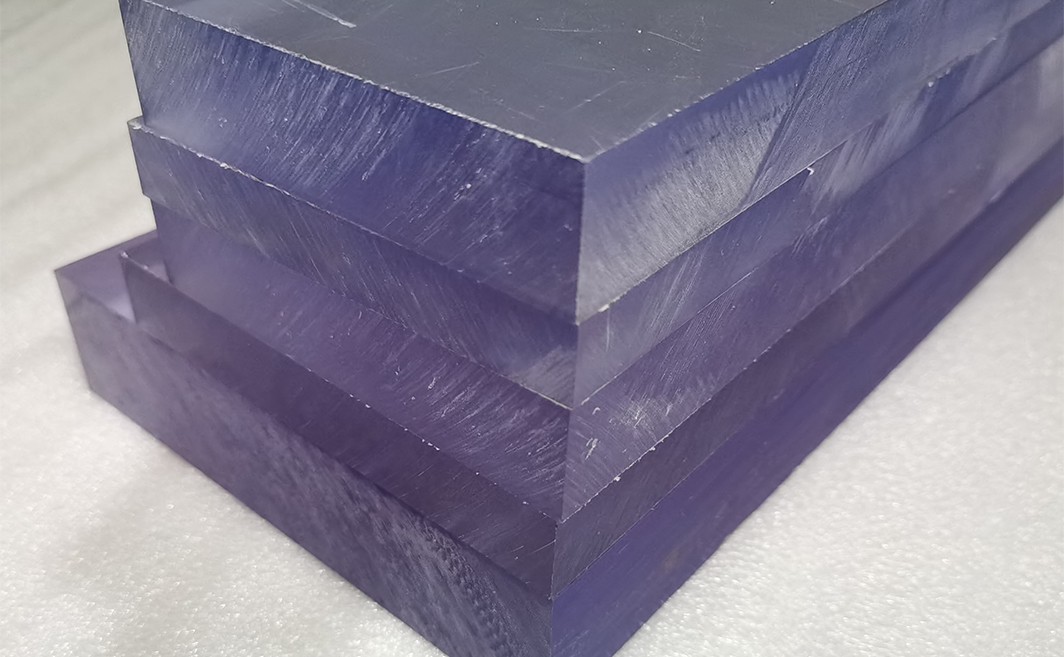

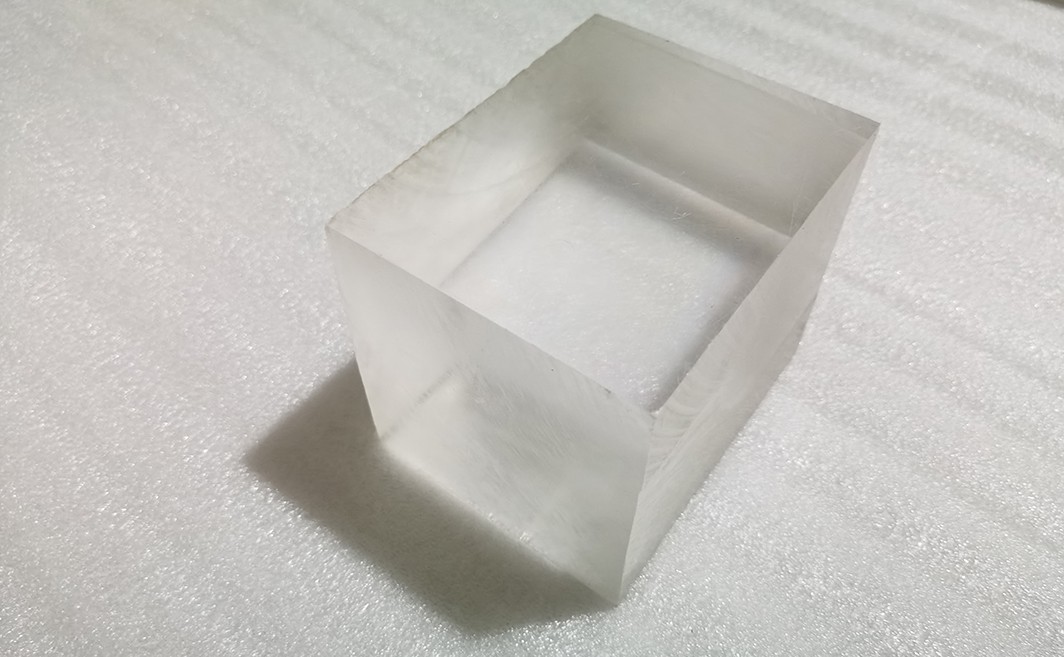

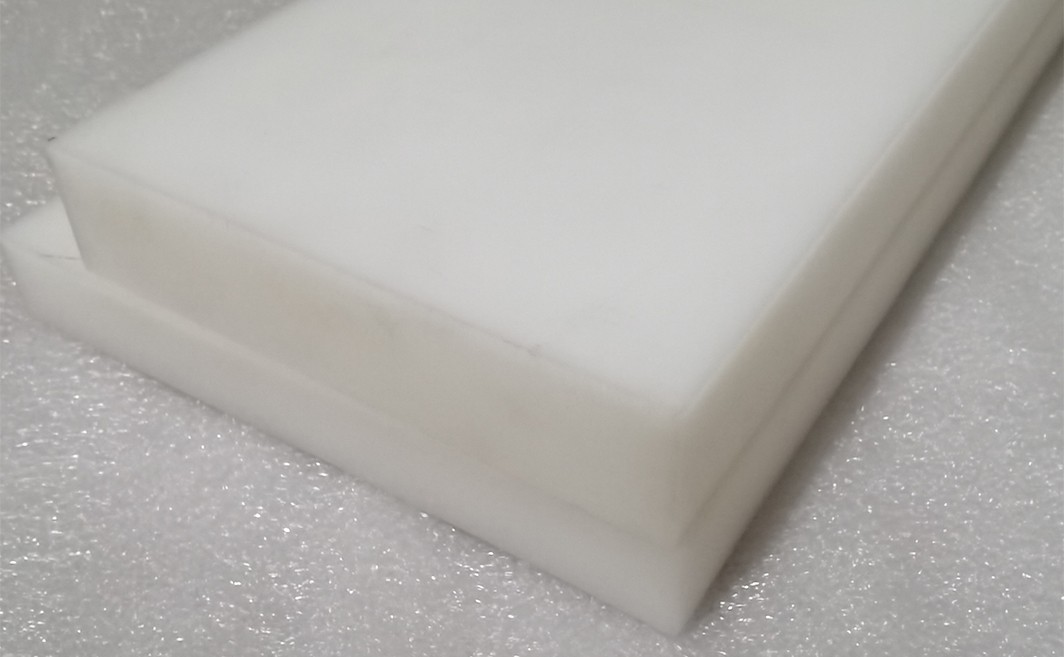

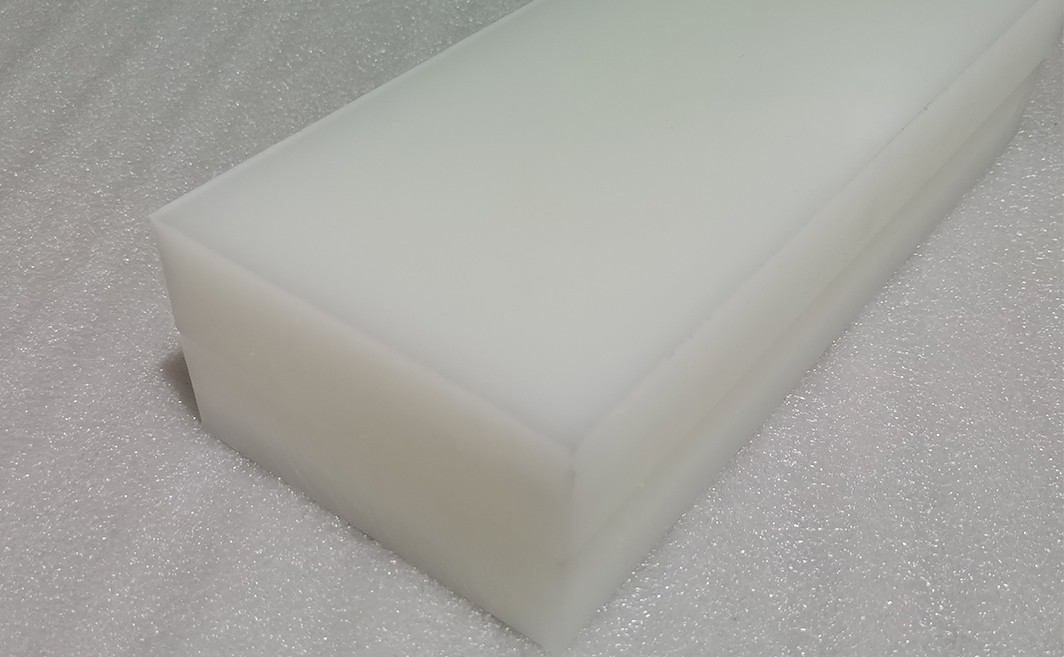

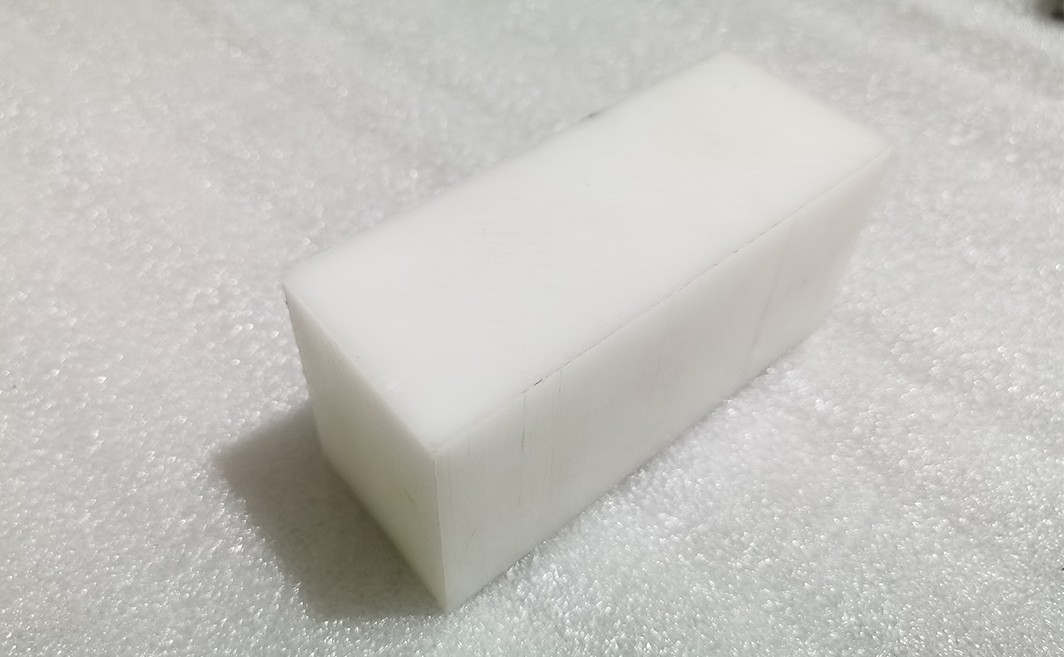

Our CNC machining capabilities

CNC machine all types of parts, from simple “as machined” workholdings to complex geometries. Our manufacturers operate almost every kind of 3/4/5 Axis CNC Milling and Turning center, with EDM and Grinders available on request. We offer tolerances down to 0.05 mm (0.0020 in) and lead times from 5 business days.