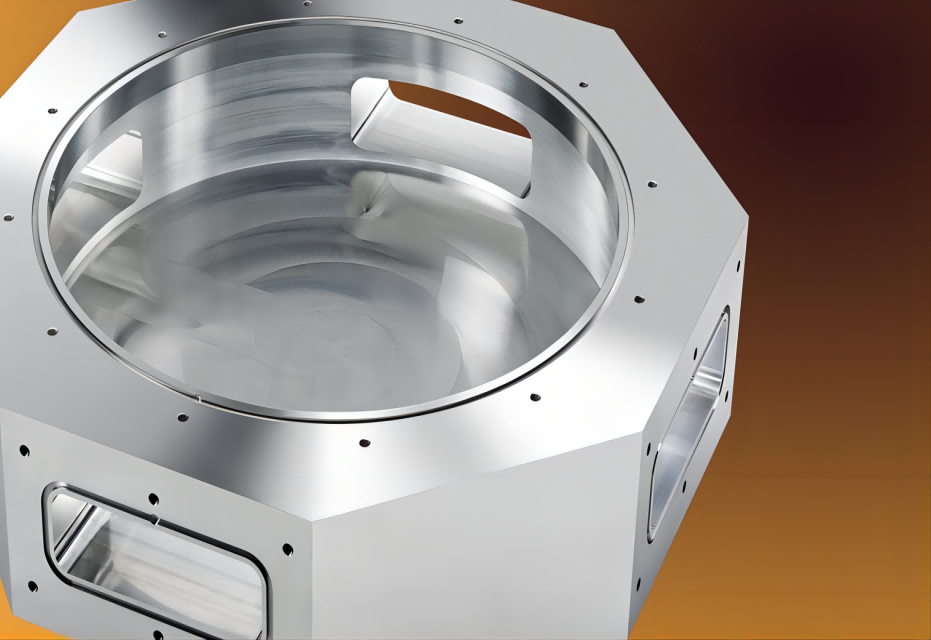

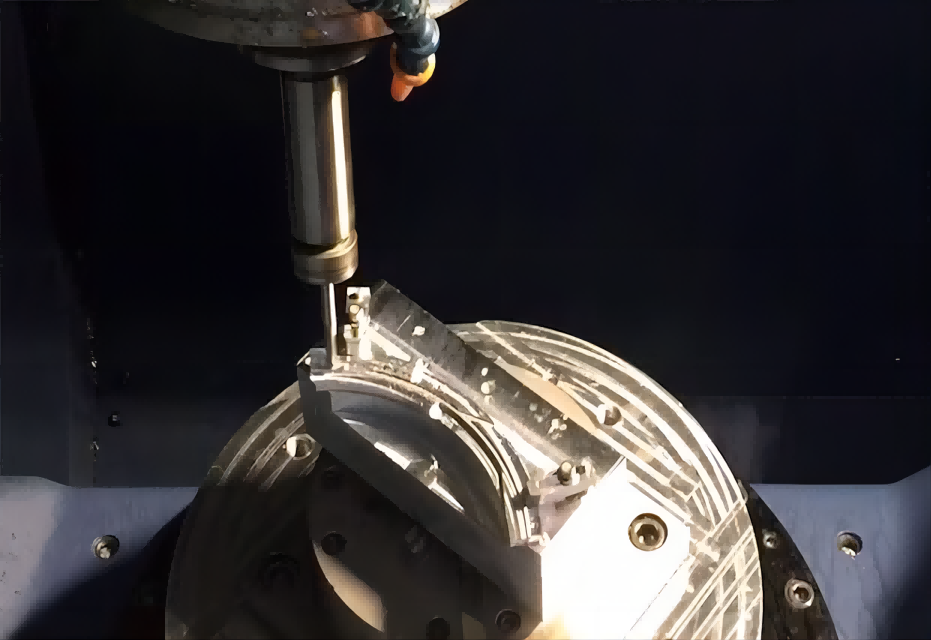

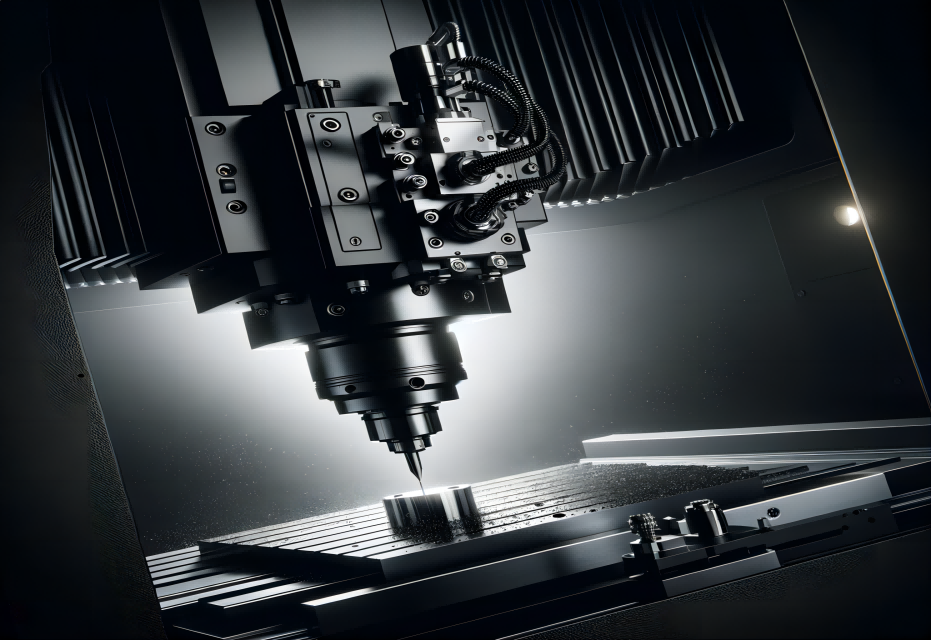

Semiconductor equipment serves semiconductors, which can be divided into etching and deposition equipment, thin film deposition equipment, cleaning equipment, wet processing equipment, packaging and testing equipment, polishing equipment, silicon wafer manufacturing equipment, etc.